Brevik CCS plant, Heidelberg Materials

What is Carbon Capture and Storage?

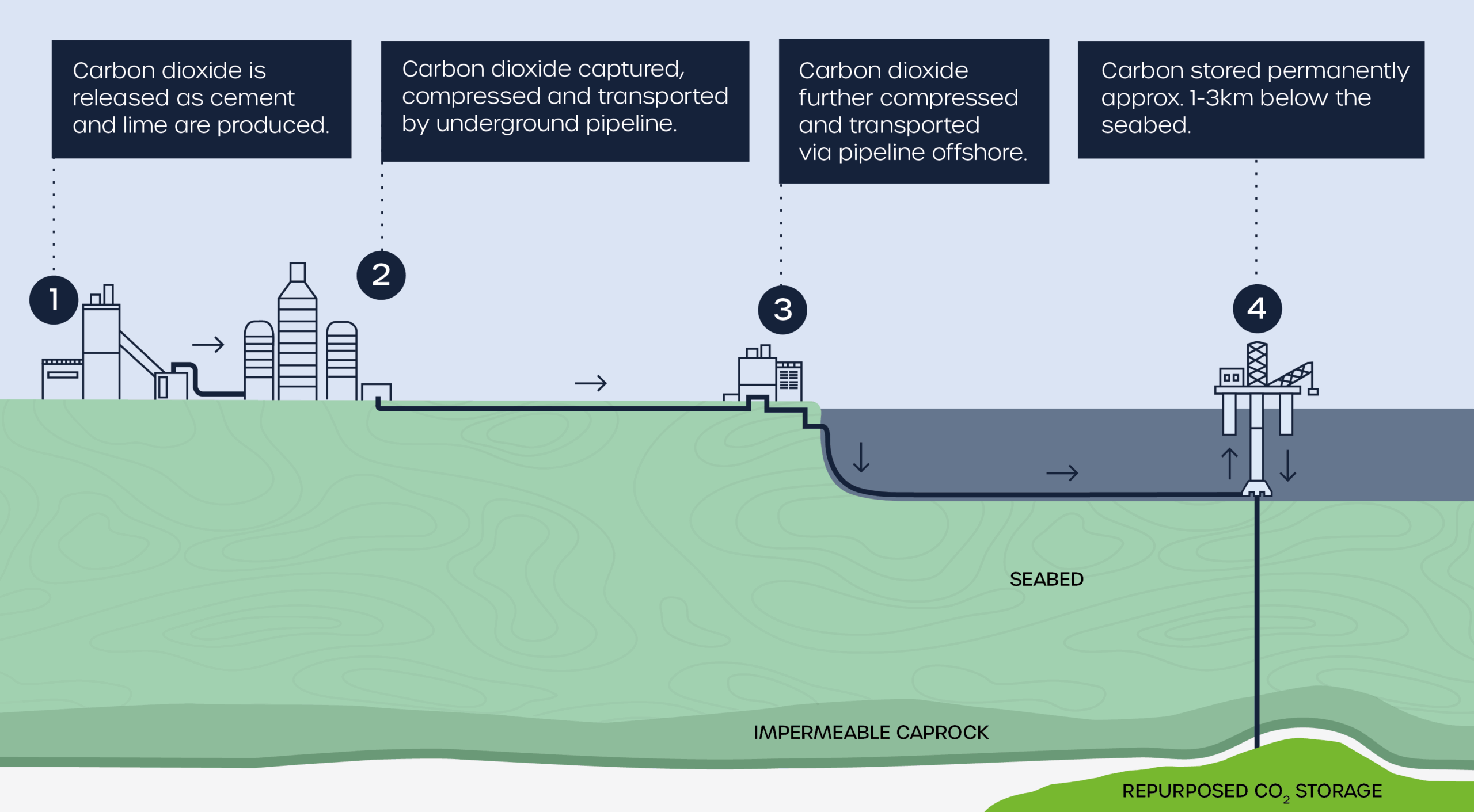

Peak Cluster will use a well-established technology called Carbon Capture and Storage – also known as CCS. This process captures carbon dioxide emissions before transporting them to secure storage sites where they will be permanently locked away.

The CO2, which is currently emitted into the atmosphere when cement and lime are produced, will be captured in purpose-built facilities situated on the cement and lime plants. It will then be compressed so that it can be transported safely by new, purpose-built underground pipelines to Morecambe Net Zero (MNZ), a store located deep under the seabed in the East Irish Sea.

MNZ is made up of depleted gas reservoirs located in Morecambe Bay which have safely and securely held natural gas under high pressure for millions of years. Over the last few decades, the gas has been extracted to heat our homes and power our industry. The stores are now ready to be repurposed to store our carbon dioxide emissions. More information on MNZ can be found on their project website.

To transport the CO2 from the cement and lime plants to the store, we considered all options including using trucks, trains and a pipeline. To ensure emissions are not increased through transport and more trucks on the road, a pipeline was found to be the best solution.

Why do we need to use CCS?

To produce cement and lime, the raw material, limestone (calcium carbonate) must be converted into calcium oxide. The chemical process cannot be changed, so CCS is the only way in which emissions can be cut from cement and lime production.

CCS is a mature technology that can capture up to 95% of the CO2 emissions produced in industrial processes.

How it works

“We’re modernising the cement and lime industry, delivering vital carbon capture infrastructure and creating jobs across Derbyshire, Staffordshire and the North West to put more money into working people’s pockets.”

Chancellor Rachel Reeves, July 2025